CNC stands for “Computer Numerical Controlled,” which refers to the fact that the laser cutter is a sort of machine that is controlled by a computer. A piece of artwork may be designed by a designer using some kind of design tools, and then that artwork can be sent to a laser machine to be cut out automatically with the simple touch of a button. After a design has been uploaded and delivered to the laser cutter, it will utilise a laser to either cut or etch the material that is placed just on the cutting bed. Since they can be used to create such a wide variety of design styles, laser cutters are an excellent all-around tool.

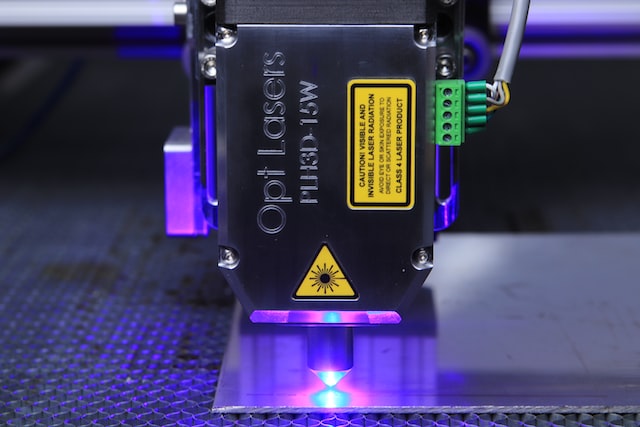

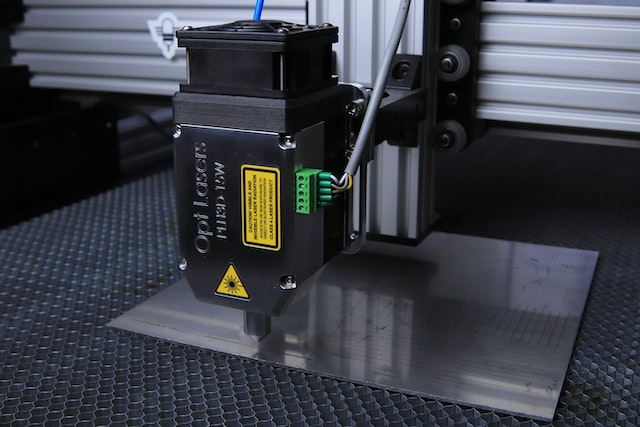

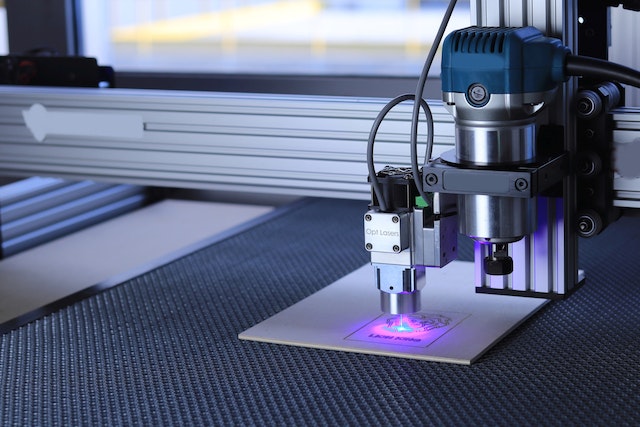

There are several variations on the basic concept of utilising a laser to slice through a material, and each of these variations results in a somewhat different laser cutter. The laser is produced by a laser resonator, that emits a powerful beam of light that travels towards the cutting head by reflecting off of a series of mirrors along the way. The laser is directed via a lens included inside the cutting head, which causes it to be focused into an incredibly narrow and concentrated beam. This beam is thrown downward at the material, and it is capable of cutting or rastering the raw stock, both of which I will discuss in further detail later. The cutting head is typically mounted on a mechanism that is referred to as an XY gantry. This is a mechanism that is driven, typically by a belt or chain, and it enables precise movement of the cutting head inside a given rectangular grid, the size of which corresponds to the dimensions of the work bed. If you want a good laser cutter, look into spectrum laser Melbourne

It is possible to produce accurate cuts at any location on the bed thanks to the gantry, which enables the laser head to travel back and forth as well as forwards and backwards over the work item. For the laser to be able to perform the cutting action, the main focus of the lens—the point at which the laser will be at its most concentrated and effective—needs to be positioned on the material’s surface for it to slice through. Before a laser cutter can begin creating cuts, it must first go through a focusing process for the laser to perform effectively.

The kinds of lasers that are included inside the various models of laser cutters are what give these devices their distinctive characteristics. Because various laser types have varying power ranges, the kind of material and the thickness of material that a laser can cut through are both determined by the type of laser. Reduced power lasers are often used for a wider variety of thinner materials that have a greater possibility for ignition, such as paper and card stocks, timber, and certain plastics. Higher energy lasers are typically employed on an industrial level to cut away huge pieces of steel plate or plastics.